DfMA aims to simplify the manufacturing of construction modules and enhance efficiency of assembly. The construction components are manufactured with the most-effective materials and processes at off-site facilities, to minimize operations on-site and assembling them at reduced cost, which helps to enhance the quality of construction, minimize construction time and enhance site safety. In order to apply DfMA successfully, the manufacturing process of the components must be well understood and collaborative approaches must be adopted. The use of BIM 3D model can visualize the assembly process of dfMA construction modules, which enhances the design efficiency and accuracy of DfMA construction solutions.We plan to adopt DfMA technique in the construction of the maintenance corridor, sewage pumping station and box culvert cell.

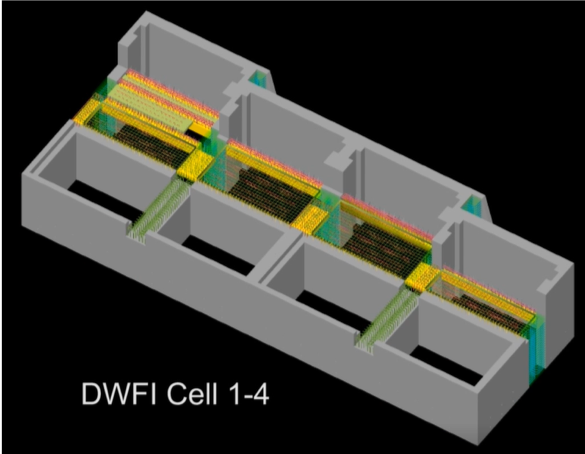

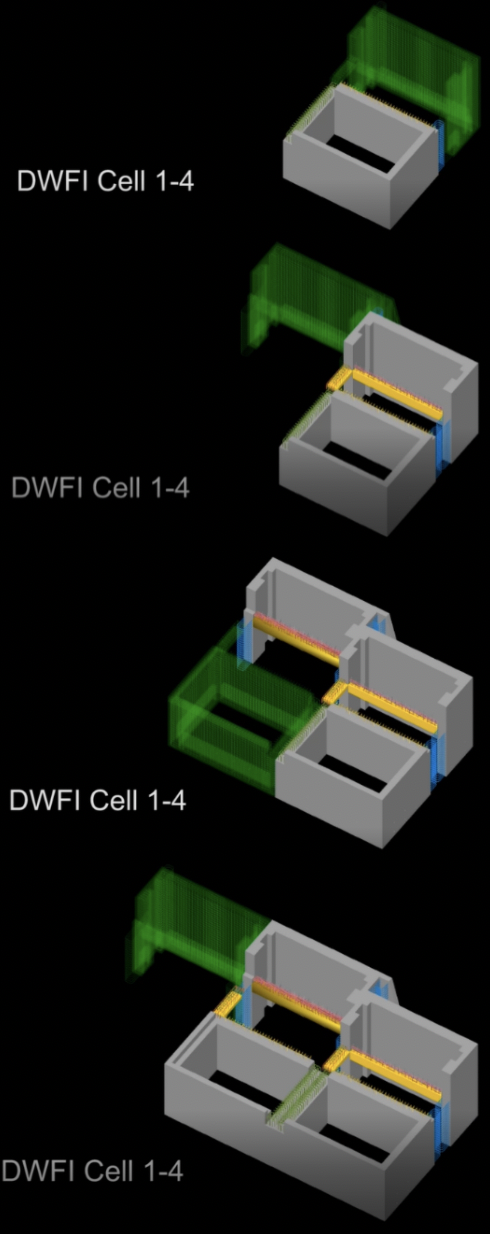

Use of BIM model to illustrate the construction sequence of the DfMA segments for Maintenance Corridor

Using the BIM Model to demonstrate

the construction process of maintenance corridor